Kolkata, India ![]() GST No.19AAHCA8267H1Z9

GST No.19AAHCA8267H1Z9

Call us now

08071930595GI Angle

85.00 - 95.00 INR/Ton

Minimum Order Quantity : 1 Tons

Delivery Time : 3 Days

Weight Varies with size (e.g., 1.13 kg/m for 25x25x3mm)

Usage Building, Towers, Fabrication, General Engineering

Thickness 3 mm to 10 mm or as required

Tensile Strength Approx 410 MPa (varies by grade)

Surface Galvanized (Zinc-Coated)

Steel Type Mild Steel (MS)

Steel Standard IS 2062, ASTM, JIS, DIN

Steel Product Type Angle Bar

Size 25x25x3mm to 100x100x10mm or as specified

Shape L Shape / Angle

Recyclable Yes

Product Name GI Angle

Product Form Angle / Bar

Material Grade IS 2062 E250/E350 or as specified

Material Composition % Iron 98%, Carbon 0.18-0.23%, Zinc coating up to 275 gsm

Heat Resistance Yes

Hardness Approximately 120-150 HB

Grade IS 2062, ASTM A36, Custom grades available

Finish Type Galvanized

Dimension (L*W*H) As per requirement (Common sizes: 25x25 mm to 100x100 mm, Length: 6 Meter)

Diameter N/A (applies for rods/pipes)

Corrosion Resistant Yes, due to galvanization

Composition Iron, Carbon, Zinc coating as per galvanization

Color Silver / Metallic Gray

Coating Type Hot Dip Galvanized

Application Construction, Industrial, Structural support, Framing, Fencing

Supply Ability 100000 Per Week

Main Domestic Market All India

About this product

Versatile Applications and Reliable Uses of GI Angle

GI Angle bars are ace components in construction, industrial installations, and general engineering. Their sharp straight edges and robust structure make them suitable for framing, fencing, structural support, and fabrication in buildings, towers, and custom frameworks. These galvanized steel angles are regularly used in projects requiring reliable load-bearing, resistance to corrosion, and adaptability in various shapes and sizes, making them unparalleled for both indoor and outdoor applications across multiple industries.

Robust Supply Ability & Seamless Order Execution

As a leading manufacturer, supplier, and distributor from India, we ensure terrific order processing, quick dispatch, and secure delivery of GI Angles to customers worldwide. Our product is available ex-stock or on a made-to-order basis, supporting orders as per customer requirements. We accept a range of payment terms to ease business internationally. With our well-organized export process, GI Angles are regularly delivered to major export markets with efficiency and reliability, guaranteeing excellent value and service.

FAQ's of GI Angle:

Q: How are GI Angles typically used in construction and industrial applications?

A: GI Angles are widely used as framing elements, structural supports, fencing components, and in general engineering due to their sturdy L-shaped design and corrosion-resistant galvanized finish.Q: What are the benefits of choosing a zinc-coated GI Angle for my project?

A: Zinc-coated GI Angles provide unparalleled corrosion resistance, extending the lifespan of structures exposed to harsh weather or industrial environments. The galvanized layer ensures lasting durability and reduced maintenance costs.Q: Where can GI Angles be stored to maintain their quality?

A: To maintain their ace quality, GI Angles should be stored in a dry area, away from moisture, to prevent surface corrosion and preserve the integrity of the zinc coating.Q: When can I expect delivery after placing a GI Angle order?

A: Order processing and quick dispatch are our priorities. Delivery timelines depend on order size and customization, but stock items are often delivered promptly, while made-to-order items are dispatched as soon as manufacturing is complete.Q: What is the minimum order quantity for GI Angles?

A: We offer flexible order sizes with no fixed minimum order quantity; orders are accepted as per customer requirements, ensuring unparalleled value for both small and large projects.Q: How is quality ensured in the production of GI Angles?

A: Our GI Angles are manufactured as per IS 2062, ASTM, and other international standards, with strict adherence to dimensions, camber tolerance, and galvanization quality, ensuring high-performance products for every application.GI Channel

85.00 - 95.00 INR/Ton

Minimum Order Quantity : 1 Tons

Delivery Time : 3 Days

Supply Ability 100000 Per Week

Main Domestic Market All India

About this product

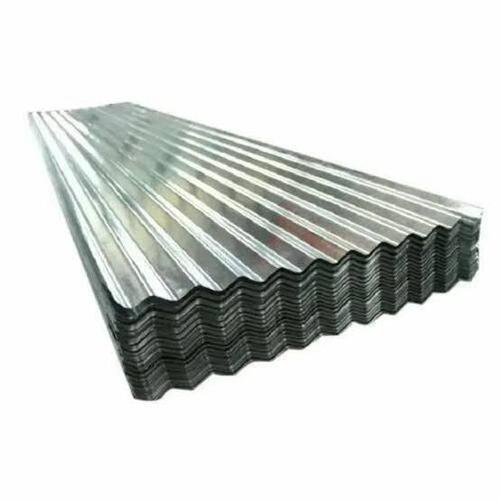

GI Sheets

85.00 - 95.00 INR/Ton

Minimum Order Quantity : 1 Tons

Delivery Time : 3 Days

Supply Ability 100000 Per Week

Main Domestic Market All India

About this product

GI Beam

85.00 - 95.00 INR/Ton

Minimum Order Quantity : 1 Tons

Delivery Time : 3 Days

Weight 38 kg (approx. for 6 m length)

Usage Support Structures, Bridges, PEBs, Warehouses

Thickness 5.5 mm

Tensile Strength 370-410 MPa

Surface Galvanized

Steel Type Galvanized Iron

Steel Standard IS 2062, ASTM A36

Steel Product Type Beam

Size 100 mm x 50 mm, other sizes available on request

Shape I-Beam / H-Beam

Recyclable Yes

Product Name GI Beam

Product Form Rolled Beam

Material Grade A/B/C (IS 2062 Gr.)

Material Composition % C: a 0.23%, Mn: a 1.5%, Zn Coating: 80-120 gsm

Heat Resistance Yes

Hardness 120-180 HB

Grade IS 2062 or Equivalent

Finish Type Smooth Metallic

Dimension (L*W*H) 100 mm x 50 mm x 6 m

Diameter N/A (Beam Section)

Corrosion Resistant Yes, due to Galvanization

Composition Mild Steel with Zinc Coating

Color Silver Grey (Metallic)

Coating Type Hot Dip Galvanized

Application Structural Construction, Industrial Fabrication, Building Frameworks

Supply Ability 100000 Per Week

Main Domestic Market All India

About this product

Outstanding Applications and Advantages of GI Beam

The GI Beam stands out as an exceptional support solution for bridges, warehouses, PEBs, and building frameworks. Its hot dip galvanized coating offers sustained corrosion resistance, making it suitable for outdoor and demanding industrial environments. Crafted for enviable structural integrity, it is ideal for use in load-bearing frameworks, with smooth metallic finishes enhancing its appeal. The GI Beam's adaptability ensures relevance across multiple sectors, including construction, fabrication, and large-scale infrastructure projects.

GI Beam Packaging, Payment Terms, and Supply Ability

Our GI Beams are securely bundled with steel straps to facilitate safe transportation and storage throughout India and beyond. With commanding supply capabilities and a robust export market network, every order is efficiently processed according to quantity - typical lead time is 7-15 days. Payment terms are flexible and can be customized as per client requirements to ensure seamless transactions. Reliable logistic partners ensure prompt supply to distributors, manufacturers, and traders nationwide.

FAQ's of GI Beam:

Q: How can GI Beams be used in structural construction and industrial projects?

A: GI Beams are commonly used as primary support structures in buildings, bridges, warehouses, and modular frameworks due to their exceptional strength, corrosion resistance, and fire safety features.Q: What are the key benefits of using hot dip galvanized GI Beams?

A: Hot dip galvanized GI Beams offer superior corrosion resistance, increased durability, and require minimal maintenance, making them highly suitable for both indoor and outdoor applications.Q: When can I expect delivery of GI Beams after placing an order?

A: Delivery lead time typically ranges from 7 to 15 days, depending on the order quantity and customer location. Customized orders may take additional time based on specifications.Q: Where should GI Beams be stored for best preservation?

A: It is recommended to store GI Beams in a dry, covered area to prevent moisture accumulation and maintain the integrity of the zinc coating, ensuring longevity and consistent performance.Q: What is the process for ordering customized lengths or sizes of GI Beams?

A: Customers can specify their required sizes and lengths while placing an order. The manufacturer will produce and supply GI Beams tailored to project specifications, ensuring precise fulfillment.Q: How does the exceptional weldability of GI Beams benefit fabrication work?

A: Excellent weldability allows for seamless joining and fabrication of GI Beams, facilitating efficient construction, modification, and assembly in complex projects without compromising structural integrity.GI Plate

85.00 - 95.00 INR/Ton

Minimum Order Quantity : 1 Tons

Delivery Time : 3 Days

Supply Ability 100000 Per Week

Main Domestic Market All India

About this product

GI Flats

85.00 - 95.00 INR/Ton

Minimum Order Quantity : 1 Tons

Delivery Time : 3 Days

Weight Approx. 1.57 to 12 kg/m depending on size

Usage Structural & General Purpose Fabrication

Thickness 2 mm to 10 mm

Tensile Strength Between 350 to 550 MPa

Surface Galvanized (Zinc Coated)

Steel Type Mild Steel with Galvanization

Steel Standard IS 2062, ASTM, JIS, EN

Steel Product Type Flat Bar

Size Customized (Common: 25x3 mm, 50x6 mm, 75x10 mm, others)

Shape Rectangular Flat

Recyclable Yes

Product Name GI Flat

Product Form Flat Rectangular Bar

Material Grade IS 2062 Gr A/B, or Equivalent

Material Composition % 98% steel, 2% zinc coating (typical)

Heat Resistance Yes

Hardness 120-180 HB

Grade IS 2062, ASTM A36

Finish Type Smooth, Zinc Galvanized

Dimension (L*W*H) Varies, typically available in customized lengths (e.g., 6m, 12m), width from 20 mm to 150 mm, thickness from 2 mm to 10 mm

Diameter Not Applicable for Flats

Corrosion Resistant Yes, owing to galvanization

Composition Mild Steel Base with Zinc Coating

Color Silver/Grey

Coating Type Hot-dip Galvanized

Application Construction, Industrial, Fabrication, Fencing, Structural Support, Automobile Chassis

Supply Ability 100000 Per Week

Main Domestic Market All India

About this product

Versatile Use & Broad Application

GI Flats are a must-have for contractors, fabricators, and builders across diverse industries. Used by professionals in construction, industrial fabrication, fencing, and automobile chassis manufacturing, these top-notch flat bars serve as reliable structural supports and plant equipment components. Their formability and superior galvanization allow seamless integration in multipurpose plant applications, offering users a long-lasting solution that meets stringent project requirements.

Export Markets, Certifications & Swift Delivery

Our GI Flats enjoy a glorious reputation in global markets, including the Middle East, Southeast Asia, Europe, and Africa. Sale price options and exchange programs make procurement simple for buyers worldwide. All flats are IS, ASTM, JIS, and EN certified, constantly meeting international quality benchmarks. Enjoy prompt dispatching-with typical delivery times of 2-4 weeks from order, ensuring your project timelines are maintained.

FAQ's of GI Flats:

Q: How should GI Flats be stored to prevent corrosion?

A: GI Flats should be stored in a dry, covered area to avoid exposure to moisture, which can lead to white rust formation on the galvanized surface.Q: What makes GI Flats corrosion resistant?

A: These flats are coated with a zinc layer (60-120 gsm) through hot-dip galvanization, providing strong resistance against rust and corrosion.Q: When will my GI Flats order be dispatched?

A: Orders are typically dispatched within 2-4 weeks after order confirmation, depending on size, customization, and manufacturer policy.Q: Where are GI Flats mainly used?

A: GI Flats are primarily used in construction, industrial fabrication, fencing, structural support, and automobile chassis projects.Q: What is the process for cutting or drilling GI Flats?

A: GI Flats offer good formability and can be easily cut or drilled using standard metalworking tools, making them suitable for various fabrication needs.Q: How does the quality of GI Flats comply with standards?

A: Our GI Flats conform to IS 2062, ASTM, JIS, and EN standards, ensuring top-notch structural integrity, tensile strength, and surface quality.GI Pipe

110 INR/Kilograms

Minimum Order Quantity : 100 Kilograms

Delivery Time : 3 Days

Surface Hot-Dip Galvanized

Steel Type Stainless Steel

Steel Product Type Galvanized Steel Pipe

Shape Rings

Product Name GI Pipe

Color Silver

Application Construction

Supply Ability 100000 Per Month

About this product

Explore Additional Categories

Contact Us

Our Products

Our Products